Controlling Instruments with GPIB, Ethernet, USB…or What is Next?

Which Bus is Best for Instrument Control?

Selecting the right computer bus for your test equipment is a little bit of a moving target but fortunately is moved fairly slowly and moving in the direction of better.

RS-232 – originating back in the early ’60s, RS-232 was developed as a standard for serial digital communication. Connecting computers to other computers or remote instrument communication with a minimum number of wires was the primary use. For a while, it became the most popular standard for sending data computer to computer or between instruments and computers, especially over phone lines with the use of a modem to couple the signal long-distance over existing phone lines.

By current standards, RS-232 is limited by the low transmission speeds, large connectors, and relatively large voltage swings required. For instrumentation purposes it is limited as well by the fact that a given RS-232 link is single-ended, that is one RS-232 port would be required for each instrument to be communicated with.

GPIB – In the late ’60s seeing the need for something better, Hewlett Packard developed the HP-IB computer bus (Hewlett Packard Interface Bus). which is now more frequently referred to as GPIB (General Purpose Interface Bus) or IEEE-488, the name of the formalized standard for the interface. GPIB boasted good speed due to the 8-bit parallel nature of the bus, meaning that 8 bits of synchronized data are transmitted at each interval of communication, theoretically making it faster. One other great advantage of the GPIB over RS-232 communication is that multiple instruments could share the same bus or network, thus reducing the number of ports required on a host computer. The downsides of this interface were that it was often troublesome to set up and hardware, connections, and cabling were all very bulky and expensive. GPIB cables are often difficult to route through equipment racks and have limited bend radius and maximum allowable run from device to device.

Ethernet – Conceived in the ’70s began its development at Xerox as an efficient computer to computer networking technology and eventually became refined and standardized in the early 80’s to be much of what we know today, displacing competing for network technologies such as Token Ring and Token Bus. Originally, the coaxial cable form is known as 10BASE-5 then 10BASE-2 gave way to the form we know today as 10BASE-T, denoting twisted pairs in lieu of the more troublesome and expensive coaxial form. This shift to twisted pair gave the Ethernet a great boost in reliability, cost and speed, and eventually market share.

Ethernet, because it was originally developed more for computer communication had in some cases been considered less suitable for instrument communication due to the lack of some instrumentation features such as group trigger, designed to allow several instruments to take a measurement at the same instant. Further, Ethernet had been considered less deterministic in general, meaning that exact timing and synchronization of events is less well-controlled even though it is generally much faster.

In 2005, LXI, or LAN eXtensions for Instrumentation standard was Introduced. Although not all LAN-based instruments need or support this extra functionality it effectively resolves the indeterminate conditions of the bus by providing timing and trigger functions based on the IEEE1588 standard. Additionally, HiSLIP (High-Speed LAN Instrument Protocol) enhances the LAN’s capabilities to work well with instruments.

USB – Universal Serial Bus, was developed in the mid-’90s as the next step in communication for the PC beyond RS-232. Primarily for hooking peripheral devices, providing more standardization with plug and play, faster communication plus sharing of a port between several devices(often with a simple internal or external hub). As an added bonus, the USB can often provide the needed power to operate peripheral devices. With regard to instrumentation systems, USB has developed some following as a low cost, easy to implement communication method for measurement. At least partially due to the fact that all modern computers now have USB ports built-in. Several major manufacturers of test equipment now offer equipment with USB communication capabilities for easy automation projects. The latest iterations of USB with yet higher speed make it a very capable system for many instrumentation needs. The USB specification even has some well-defined Test and Measurement Class (USBTMC) of protocols for instrumentation and emulating GPIB data type transactions.

Still GPIB…While the tide is slowly turning more towards Ethernet at this time, GIPB continues to amaze people with its persistence. While so much in the tech world is very fast to change to newer cheaper and better technology, GPIB remains surprisingly entrenched in the test and measurement arena. With easy-to-implement devices such as National Instruments ENET/100 that can translate from GPIB to Ethernet, it is not very difficult to cope with an existing legacy device that may still be required that only supports GPIB and not Ethernet. It seems to be the belief of most of the Test and Measurement community that in time, Ethernet, often with an isolated network will prevail as the dominant interface between instruments and PCs.

Structured Programming – Structured Programming is a programming paradigm making extensive use of subroutines and block format structures. It follows through to many higher-level languages improving troubleshooting, and maintenance of the software. Emerging back in the ’60s the need to make coding more precise, deterministic, reusable, and verifiable, Structured Programming is now accepted as good practice yet is still resisted by some. Proper use of structured programming facilitates among other things, easy transition from legacy protocols and busses to more current technologies. While there is some value in the “if it is not broke then don’t mess around with it” thought process, inevitably at some point in the future there will be motivation for change in the forward direction. Having structured programming in place that is modular and easily maintainable will enhance any system that is not already doomed to a fixed lifespan. Having seen the changes over the years, it is not likely that the changes in instruments or computer busses will come to a halt soon.

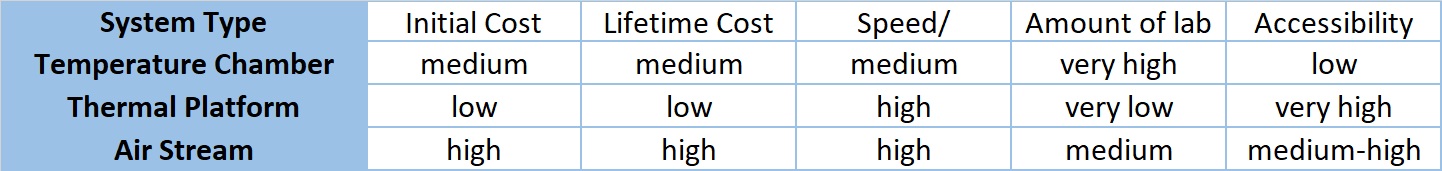

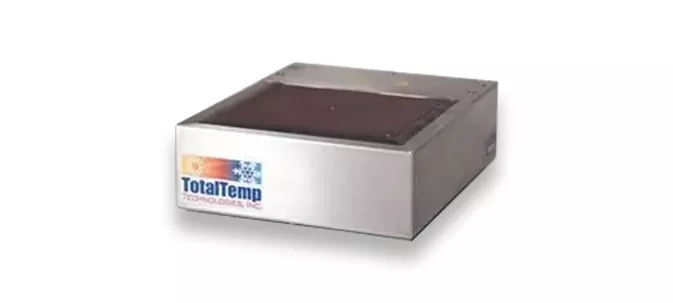

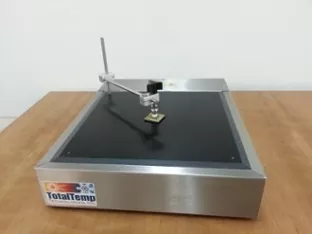

VXI and PXI – Two other bus structures for communication with instruments are of note here as well, PXI and VXI, both of these are substantially instruments without user interfaces, built on the architecture of existing computer bus technology. VXI is a VME computer bus extended for Instrumentation and the PXI is PCI bus extended for Instrumentation. These instruments must live in a host computer or bus expansion chassis. They cannot stand alone like the usual benchtop instruments but rely on the host computer to operate. They are often implemented when instruments are dedicated to a task and are not really required to have front panel controls and displays. There can be notable cost and space savings by the integration with the computer as the sole user interface or control mode. Only a few instruments are really hard to find in PXI or LXI form, Temperature chamber/Thermal platforms controllers would be one of those hard to find in VXI or PXI form. In this case, Ethernet can easily control the Thermal conditioning system while other instruments still enjoy the benefits of the integrated system.

VISA – Virtual Instrument Software Architecture (a standard under the control of Interchangeable Virtual Instrument or IVI Foundation) is a widely used input/output application programming interface used for facilitating communicating with instruments from a PC The specifications included in The VISA data structures make it far easier to change instruments commands or change communication busses without dismantling the whole structure of existing test software. Most of the larger instrument manufacturers implement the VISA structures in their instruments. Following these protocols produces robust determinant communication that can easily be changed, upgraded, or modified, making life much easier in the event that an instrument or existing bus structure must be replaced or upgraded.

SCPI – (Standard Commands for Programmable instruments), now also under the control of the IVI Foundation, SCPI carries the standardization and interchangeability of instruments concept yet further. If a given instrument is designed to implement the SCPI protocol, as an example, in theory, one brand of programmable voltmeter can be unplugged and another brand of voltmeter plugged in in its place to take the same reading using the same standardized command set. Even another type of instrument, perhaps a scope capable of making a voltage reading might be sent the same commands as the voltmeter and return the reading in the same format. The practical benefits to the user seem great. Many of the more mainstream vendors seem to be on board with this already although not all manufacturers have adopted these standardized commands and syntaxes.

Conclusion – It is hard to predict what might be next, we can only guess what a few of the future candidates might be, WiFi, Advancements in USB3, Bluetooth, Lightning (well scratch that one) … we will see. A number of articles have been written on the subject and although the change has been slower than many have anticipated, the inevitable fade-out of GPIB is approaching. New systems at this time should be designed around LAN-based LXI technology when possible. In some cases where cost savings are more important, USB can be considered a good choice as well. The formal protocol extensions help but bandwidth limit considerations can still apply since a slower instrument can slow down the whole bus and even in some cases the computer’s overall performance. If a more complex and dedicated system is desired and there is no apparent reason for each instrument to have its own display and control knobs, then perhaps VXI or PXI type instruments with their more tightly integrated systems can provide a good advantage in space and cost savings. RS-232 is still in wide use although most computers have skipped that interface in the move to USB The one instrument per bus capability is limiting for most instrument systems. Fortunately USB to RS-232 converters is cheap, easy to implement, and readily available.

Perhaps two reasons people are reluctant to move away from legacy GPIB systems are 1) unstructured, poorly written code that might blow up if altered, 2) the memory of struggles in setting up and troubleshooting the original configuration of GPIB test equipment. My experience is that many of the headaches involved with setting up GPIB systems stay with GPIB systems. That is to say, more modern systems are easier to design, set up and troubleshoot. That nothing could go wrong but things have improved. A lot.