Freeze substitution (FS) fixation of hydrated samples frozen in glassy ice provides exceptional structure preservation for light and electron microscopy.

It enables immunological detection of heat-labile antigens, which are otherwise damaged or destroyed by processing at room or elevated temperatures.

Its use as a clinical pathology or research tool has been limited by the relatively long periods required for the passive diffusion of fixatives and organic solvents in frozen-hydrated material.

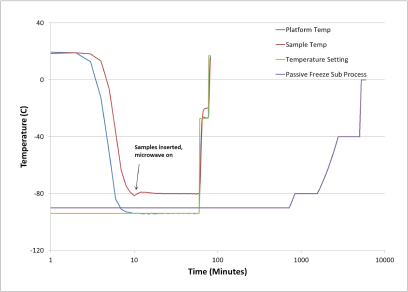

The invention uses controlled microwave (MW) irradiation to speed up the SF process; and comprises systems, devices, and methods for microwave-assisted processing of samples under cryogenic conditions, typically -80°C.

The MWFS procedure takes less than 4 hours, compared to 4-5 days previously required for the FS process.

The Cryo Microwave Sample Processor System combines two specific technologies, controlled microwave irradiation and temperature cycling.

The controlled temperature cycling device, a Temperature Chamber was specially engineered by TotalTemp, using some alternative nonmetallic materials, to allow it to operate inside of a microwave environment.

The Temperature Chamber is cooled with Liquid Nitrogen (L-N2) giving it a precisely controlled temperature range of -100°C to +200°C.

The microwave oven was provided to TotalTemp by the customer for the installation of a bulkhead interface plate to allow AC power input, L-N2, and a nitrogen gas purge to prevent excessive condensation within the microwave oven while the platform operates in cryogenic temperatures.

In addition, the nitrogen gas purge directed into a transparent polycarbonate cover, which remains on the surface of the platform.

TotalTemp machined a custom-designed adapter plate with recessed cavities to support vials and Petri dishes for thermal conduction during the FS process.

In conclusion, the microwave oven is a Ted Pella Biowave model 3451 has a special magnetron for 80 to 750W continuous power, with no pulsing power like a standard kitchen oven.

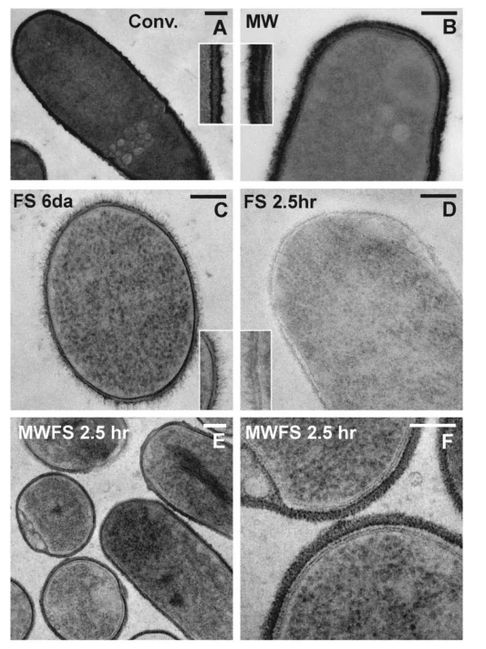

Mid-log phase cultures were prepared by conventional chemical fixation (A), MW-assisted chemical fixation (B), traditional FS (C), or by rapid FS without (D) or with MW irradiation (E-F). Inserts show detailed cell wall structure at a magnification equivalent to that in panel D. Samples processed rapidly by FS without MW irradiation exhibited poor preservation (D). Samples processed by MWFS exhibited structures such as membranes, ribosomes, and cell wall material that were obscured or poorly discernible by other techniques.

Bars: 50 nm.