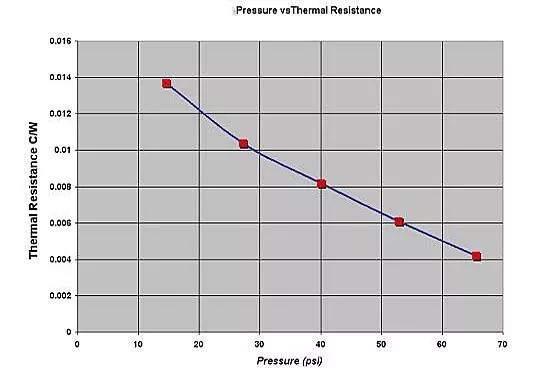

Thermal Conductivity v. Clamping Pressure

How tightly to clamp devices to a heatsink or Thermal Platform?

It is true that the more tightly you can clamp two surfaces together the better the heat transfer. This is especially important if you are looking to transfer large amounts of heat from one device to another.

Courtesy: OverClockers

If you are talking about small items that produce little or no heat, good contact is still important but the ultimate heat transfer efficiency really isn’t so critical. However, there are many cases such as dissipating the heat from millions of transistors in a CPU or high power output devices driving heavy loads, maximizing heat transfer can easily become critical. For thermal testing, it is always important to minimize temperature differences between part interfaces.

Along with the thermal conductivity, sufficient surface area and the flatness of both heat transfer surfaces clamping force are also important. If you think about it, remember that particularly if you are talking about a large surface area, what is important is the force per square inch.

Therefore larger items generally will require larger force and of course never more force than what would deform or distort the package that is looking to keep good contact with the heatsink or thermal platform. Also, higher wattage heat transfer will require better heat transfer that is possible with sufficient clamping.

Clamping Methods

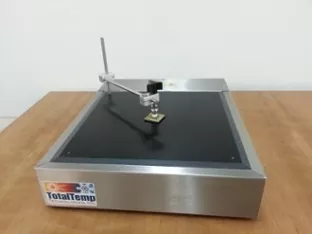

Low force single-arm clamp

Dual arm clamp set

High force Kopal Clamp

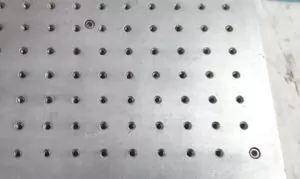

The main methods of securing devices to thermal platforms are simply screwing the device to the surface, spring clamps, or other hand tightened types of clamps. We offer light, medium, and heavy-duty clamping systems. Platforms can be directly drilled or an adapter plate can be secured on top of the platform, Adapter plates slightly slow down the performance but allow flexible or interchangeable hole patterns for specific tasks or loads. Custom cutouts and pockets are also possible to allow optimal contact to irregular surface components without making custom modifications to the surface of the platform.

Custom Adapter Plate with an array of 4-40 holes

IN CONCLUSION:

While we carefully avoided equations and theoretical heat transfer equations in this write-up, If you are producing less than 5 watts per square inch or are OK with more than a 5-degree difference between the device package and platform or heatsink then light or no clamping at all may be required. From there up, the more wattage the more clamping force required. If for example if you are trying to transfer 50 watts per square inch, you may need 20 pounds per square inch clamping force. For more specifics, we are available to review and discuss more specifics of your heating and cooling requirements.