Thermal Testing Equipment: Maximizing Value

In the world of Test and Measurement, there are numerous options for your temperature testing equipment. They can have a significant impact on costs, upfront and ongoing as well as ease and quality of results. For maximum value from your equipment, it is helpful to better understand the methods and choices available to you.

With temperature testing equipment, there is more than one choice for how to accomplish heating and cooling. In most cases, resistance heating is the heating method of choice, thus the primary basis of the decision becomes a discussion of cooling options. For cooling methods, there are several choices and the costs vary dramatically. Finding the best available value for that equipment often depends on determining the specific requirements for your unique application. Here are several factors for your consideration:

Methods of Cooling

Mechanical Refrigeration, – Closed-loop compressor-based systems.

Expendable Coolants – Cryogenics i.e. Liquid Nitrogen (L-N2) or Liquid Carbon Dioxide (L-CO2).

Thermoelectric Cooling – Peltier Chiller Systems.

Recirculating Fluid Chiller Systems and Liquid Baths.

For more details on the cooling method trade-offs visit our blog post:

Methods of Heat Transfer

Convection –

Temperature Chambers/recirculating air or Forced.

Air Systems, non-recirculating air such as a thermal airstream system.

Conduction – Thermal Platforms.

See our whitepaper on Conduction v. Convection for Thermal testing.

When choosing a chamber to meet your needs, good airflow is essential, the air ramp rate of an empty chamber will seem much faster until you put your load inside with a chamber that has low airflow.

As we learn in Physics class, conduction is the most effective process for heat transfer but it is not always possible due to the shape and geometry of the device to test.

In many cases, it comes down to choosing between a chamber or a thermal platform with the shape of the device under test dictating the choice for a chamber. Airstream systems are often a good choice for one at a time component testing but often impractical for production situations where multiple cumbersome systems or queuing of the parts to be tested would be required.

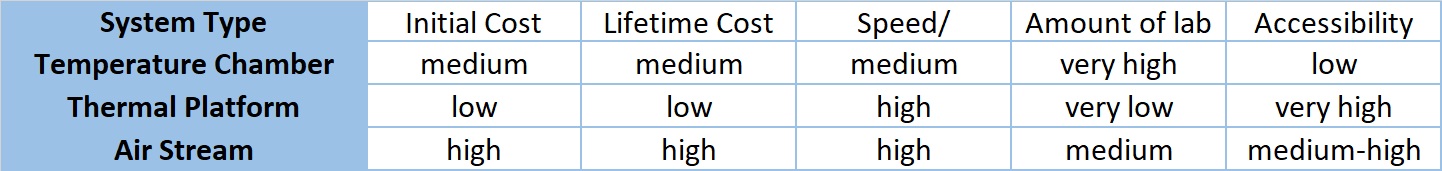

A Summary of the Main Systems Used for Thermal Testing

For versatility, standard chambers are very popular and meet the needs of a lot of testing purposes. Often they are more price competitive due to the larger scale market. Again if performance is important pay attention to airflow rates and ramping rates WITH LOAD. Higher performance often means more power, large expensive, noisy compressor systems that require maintenance, or Expendable Cryogenic coolants like L-N2. Chambers provide performance regardless of the shape of the device under test, are typically slower transitioning and settling, and require more lab space.

Forced air or airstream systems are very good for spot cooling applications, they are bulkier than thermal platforms but also less sensitive to the shape of the device. They are typically more expensive and require more power and more maintenance. They can provide fast accurate temperature control with better accessibility to the device than chambers.

Platforms control temperature by conductive heat transfer and thus are inherently faster however are restricted to devices that have a flat conductive surface or can be fixtured to work on a platform. They are generally less expensive to buy and operate. Platforms provide fast-cycling time, require little laboratory real estate, and offer very good accessibility to test objects.

The flexibility and ease of use of the temperature controller and the ability to readily produce recorded test records in an automated way is also important consideration for thermal testing value.

As you see, there are several aspects to consider when choosing thermal testing equipment.

If you would like our trained consultants to talk with you and answer any additional questions you may have.

More to follow on methods and value of combined conduction and convection heat transfer.

Example of Ten Production Thermal Platform Systems requiring far less lab space and power than other types of thermal test systems.