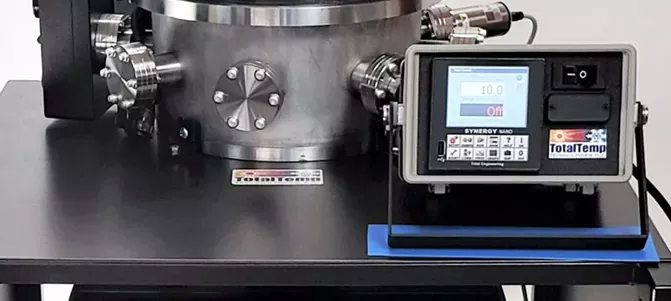

The Next Generation TotalTemp Thermal Vacuum, TVAC Chamber

The efficient advantages of thermal platforms are a natural for conductive heat transfer in high vacuum applications. With all the new hardware going into space, where service calls are rare, thermal vacuum testing is important part of testing high altitude and satellite equipment.

–70°C to +175°C, vacuum to 1×10-6 Torr

Affordable and configurable for your application. Simultaneous high vacuum and thermal testing without renting time at a test lab. Thermal platforms to fit your vacuum chamber or fully turn-key systems. Platform shown inside bell jar is 6.5” x 7.5”, other sizes and different bell jars available.

- 6.5″ x 7.5″ Usable surface area (49 sq. in / 315 sq. cm).

- 12″ square or other sizes per your requirement

- High Altitude or Space Simulation 1 x 10-6 Torr.

- Temperature Range from -70°C to +175°C.

- A typical coolant is Liquid Nitrogen.

- Heated with embedded resistance heaters

TVAC Chambers for…

Aerospace environmental testing in a thermal vacuum chamber allows for the exposing and weeding out potential problems due to temperature extremes and change in or lack of atmospheric pressure as in space. With equipment destined for space, the stakes are much higher with the cost of a launch, chances of a failure could be catastrophic plus service calls in space have historically been very costly. The game of basic thermal testing in space is a little different than testing for land-based systems, mainly because the lack of heat transfer by air. The intentional and unintentional transfer of heat by convection makes a big difference from what could be common sense solution in an environment with air.

Outgassing of many materials would be another consideration that is not such a big deal on Earth but requires careful planning for items going into space. Making sure that components headed for space are going to perform as planned typically involves simulating the environment as it is expected to be experienced in space or low Earth orbit. Standards for testing have been developed making success more predictable. Standards such as:

- MIL-STD-202

- MIL-STD-810

- RTCA/DO-160

- ISO/AWI 15104, ECSS-Q-ST-70-02C

Prior to integration into larger systems, components and subsystems can be tested far more effectively in a smaller, portable thermal vacuum chamber. Typically, larger thermal vacuum systems are only affordable by large institutions and time using them can be scheduled and rented as needed. Not only is a small portable thermal vacuum system a more affordable option but the ability to have the capability on hand as required can be a big deal. A small thermal vacuum chamber will reach vacuum level and temperature much more quickly than a large chamber and pay for itself in efficiency, convenience, and accessibility.

Cost-effective space simulation.

- Portable space simulation equipment is cheaper to acquire

- Smaller systems don’t take up as much valuable lab space to use and to store when not in use

- Faster to pull down to vacuum and fast temperature transition times result in shorter test times required to perform tests

- They are more efficient, using less power, generally not requiring special electrical services

- Smaller systems are often more time-efficient as you are less likely to have to share with others. Larger systems often require travel, time-sharing, and waiting for a scheduled-use time

The TotalTemp Platform can be integrated into an existing vacuum chamber, as is shown in the picture above, or we can provide a complete turnkey system to solve your space simulation or other thermal vacuum challenges.