Thermal Testing with Convection and Conduction… together at last!

The Hybrid Benchtop Chamber – True Thermal Testing Bliss

Combines Thermal Conduction and Convection

in one incredibly fast and efficient design

A heartfelt Congratulation is in order for the happy and successful union of two distinct thermal testing methods that are finally sharing the same dance floor together – as the first true Hybrid. To better understand the specific benefits from both sides of this collaboration of two testing methods, please review the following white paper:

Conduction vs. Convection for Thermal Testing

Typical Environmental Test Equipment used for Thermal Convection and Thermal Conduction

Thermal testing by convection is usually achieved with the use of a Temperature Chamber. For versatility, standard chambers are very popular and meet the needs of a lot of testing purposes. Chambers provide performance regardless of the shape of the device under test, are typically slower transitioning and settling, and require more lab space.

Thermal testing by conduction is most commonly done on a Thermal Platform. Platforms control temperature by conductive heat transfer and thus are inherently faster however are restricted to devices that have a flat conductive surface or can be fixtured to work on a platform. Platforms provide fast-cycling time, require little laboratory real estate, and offer very good accessibility to test objects.

Hybrid Benchtop Test Equipment Solves Many Problems

* Improves thermal uniformity gradients

* Increases throughput with faster cycle times

* Small footprint with easy access benchtop operation

* The fully-featured Synergy Nano Temperature Controller is capable of controlling platform temperature and air temperature independently or together

* Controller offers DUT and other data logging, remote access, cloud capability, and many networking functions

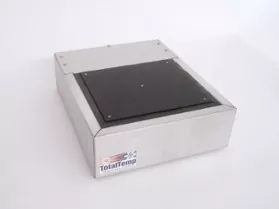

Hybrid Benchtop Chamber Test Equipment

Shown with Lid up revealing the Thermal Platform floor of the Chamber

Thermal testing is an important part of electronic manufacturing for reliability and design verification.

There are a variety of products for thermal testing and now TotalTemp is presenting a completely new and unique contender.

Temperature chambers, thermal platforms, air forcing units, and liquid baths have been around for a while and work well with many types of testing requirements. But the Hybrid Benchtop Chamber Test Equipment provides many of the best features of Temperature Chambers and Thermal Platforms together to maximize performance and control and shows new promise of filling the need for faster, superior thermal testing.

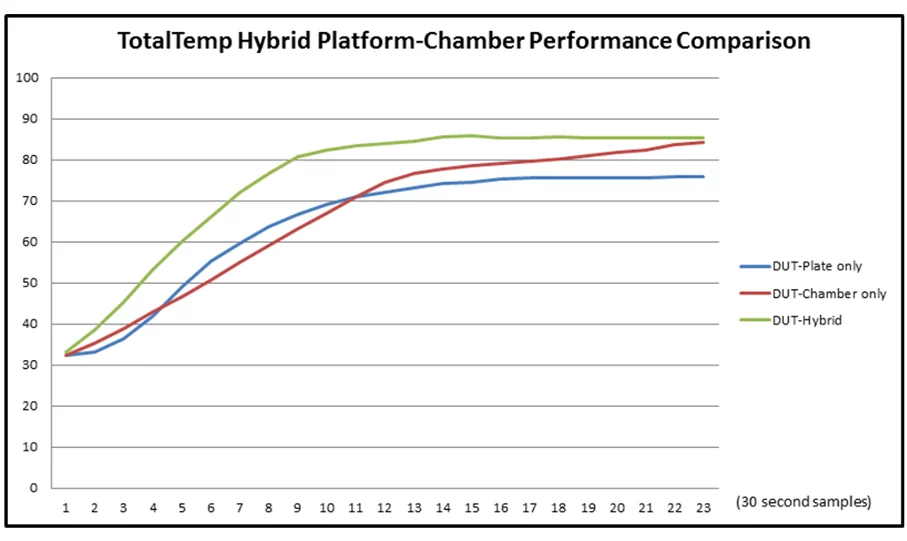

Hybrid Benchtop Chamber Has Performance Results

As shown in the data chart above, in the basic operation mode, The Hybrid Benchtop Chamber demonstrates a significant improvement in thermal test performance. The floor of the chamber is a completely functioning Hot/Cold Plate and operates independently or in conjunction with the chamber.

Because the controller is capable of advanced temperature control algorithms, it can allow even better performance by monitoring DUT temperature and allowing air and platform temperatures to be carefully controlled while verifying that required DUT temperatures are achieved.

The standard model currently available is called the HBC49-N with a thermal platform size of 6.5” D x 7.5” W, the chamber interior dimensions are 8.5” W x 7.5” D, Height is 4.5” to 6.5” at the rear. The system can be cooled with liquid nitrogen (L-N2) or liquid carbon dioxide (L-CO2) and is rated for a temperature range of -100°C to +150°C.

TotalTemp Technologies is the manufacturer of the Hybrid Benchtop Chamber. TotalTemp is a manufacturer of temperature cycling and conditioning equipment. They are located in San Diego, CA.