Thermal conductivity: Compound, Sil-pad or nothing?

Why use anything?

Why use anything?

Good thermal conductivity is important to the dissipation of unwanted heat from active power components and also important to the application of thermal platforms for testing electronics.

Perfectly flat, parallel and particle-free surfaces might show better thermal conductivity directly pressed together, however, some of the real-world realities generally prevent that best-case best performance. Here are a few reasons to use thermal grease:

- Metal surfaces that appear to the eye to be perfectly flat, free of voids and parallel are usually are not.

- Electronics like cleanliness, not all products can be built in clean rooms. A small unseen particle between two surfaces can easily prevent them from mating properly

- Keeping even pressure on two surfaces is not always as easy as it might seem. Keeping an appropriate amount of pressure on the two surfaces is important to transfer heat. Grease fills voids caused by uneven clamping pressure.

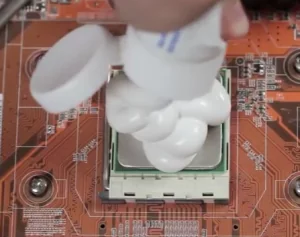

Thermal grease to the rescue?

So – given that close enough to perfect flatness, cleanliness, and parallels is hard to achieve, thermal grease has been used for decades to improve the thermal conductivity between two metal surfaces. Much has been said lately in the world of competitive computing & overclockers about heat transfer thermal grease. Generally, the most important point is less is better. There are articles and stories reporting varying levels of improvement in heat transfer from different grades of thermal transfer grease. In general, what I have seen says that the quality of the grease can make some difference and the high-end stuff is expensive but generally far from proportionally better. One youtube video even suggested Nutella, the food product that worked about as well as much thermal transfer product. Well, I’d say don’t try that but is interesting that it could work at all, even as a short-term solution. I am pretty sure over time it would shrink and prove corrosive to metals to mention a few. Properly applied thermal compounds should have little risk of making a mess over the rest of the electronics or in general. This is also a good time to note that often electrical conductivity doesn’t matter that much but depending on the application, some thermal compounds are specified to be electrically conductive and some are required to be insulating. clearly, you wouldn’t want unwanted electrical conductivity on a circuit assembly.

Silpads to the rescue from messy grease.

Silpads and similar products are pretty much what the name says, silicone-based pads used in lieu of grease and designed to be either electrically conductive or not based on the application. They compress slightly to fill in voids and are often reusable providing faster, more repeatable results. Silpads are a good solution for many heat transfer requirements. Due to their generally thicker nature, they are generally slightly less thermally conductive than a very thin layer of thermal compound. When it is important to maintain electrical isolation, they are often better than other alternatives.

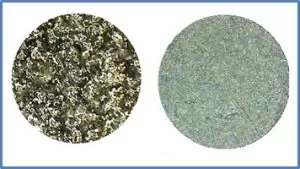

Actual “Flat” anodized aluminum surfaces at 200 X magnification

At 200x magnification, you can easily see that flat and smooth is really not flat and smooth. The one on the left might initially look and feel flat to the touch but in fact, it is not a good surface for thermal conductivity due to the voids. This photo on the left is what the result would look like with a hard anodize treatment on cast aluminum (Cast metal generally has more voids). Under a microscope the microscopic pitting is obvious.

The example on the right shows an acceptable surface for thermal conductivity however this is a view of a used thermal platform surface with a hard anodize that shows more true flatness as seen under the microscope but also shows minor wear scratches that can impede thermal conductivity. A small area of missing material is not so significant but if a ridge or pockmark prevents full contact between the surfaces, it can greatly limit heat transfer.

If the surfaces can be lapped for improved flatness better thermal conductivity will clearly be achieved.

Keeping good, even force holding the surfaces together is the final note here. It may seem obvious but in many cases, thermal conductivity is hampered by uneven pressure. Too much on one side or just not enough. More is usually better for better thermal conductivity with the limiting factors being most practical issues such as not distorting the surfaces which must have good contact.

CONCLUSION

Most surfaces are not as particle-free, flat, and parallel as they initially seem. A little thermal grease goes a long way to making for better conductivity, Silpads are less messy and also help cope with special needs such as electrical isolation and reusability but may have slightly lower heat transfer performance. Use of thermal grease and silpads together is generally not recommended as you will end up with two layers between the surfaces. Finally don’t forget secure and even clamping.