for RF Microwave and electronic testing and profiling. Customers doing this type of product testing often choose to feed through ports and heavy-duty shelves. The C460 chamber (shown here) is almost always set up for the Nitrogen purge gas option to reduce condensation within the chamber. Sizes vary, to see more size options, click here.

Temperature Chambers for mil-spec 810 tests. A United States defense standard, often called a military standard, “MIL-STD”, “MIL-SPEC”, or (informally) “MilSpecs”, is used to help achieve standardization objectives by the U.S. Department of Defense. Environmental laboratory testing as defined by and started as the United States Military Standard that tailored an equipment’s environmental design and test limits to the conditions that it will be experiencing throughout its service life. Although prepared specifically for military applications, the standard is often used for commercial products as well. The benefits far outweigh the cost as all facets of the industry have seen improved product quality and increased productivity due to more efficient test products.

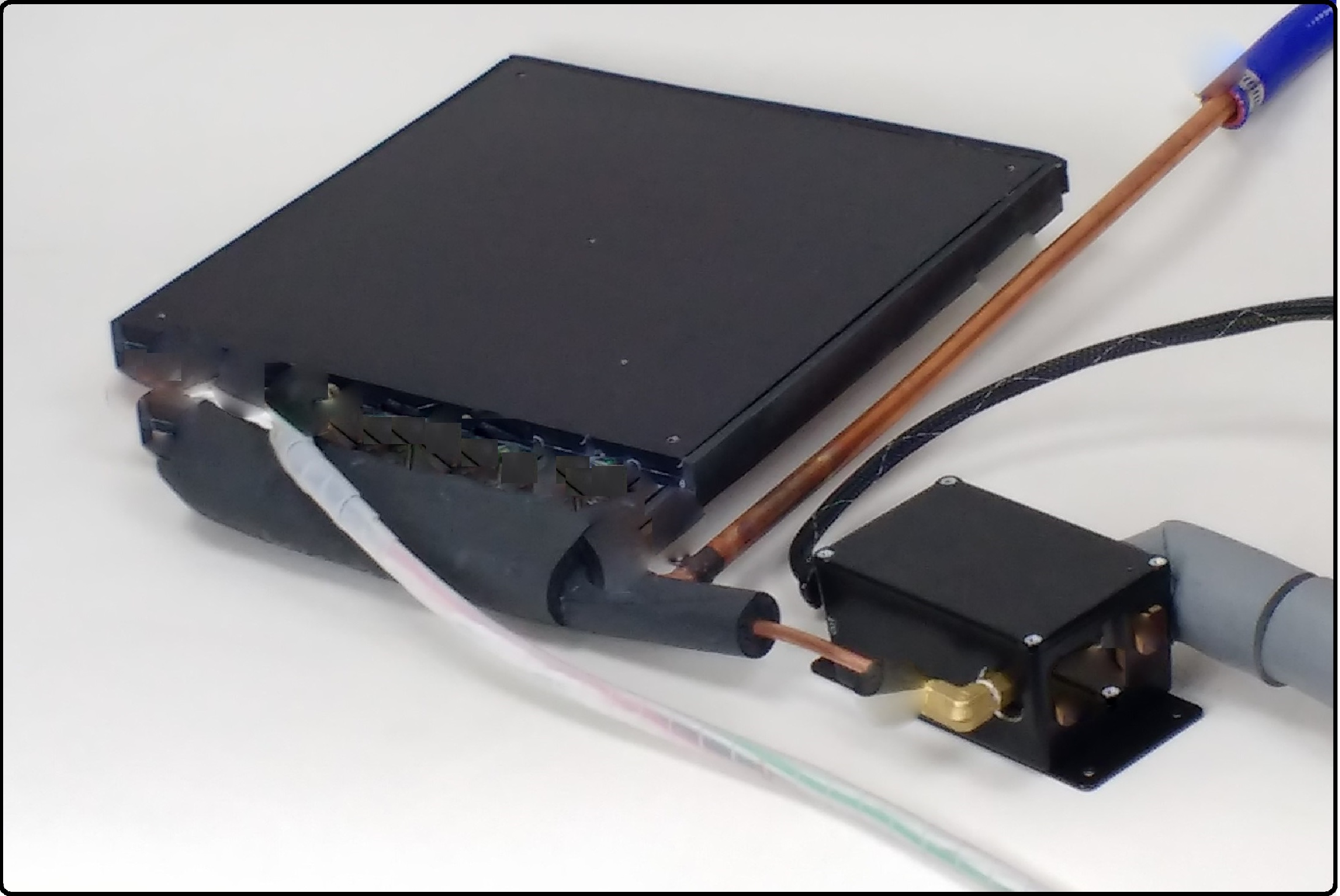

Temperature Chambers for surface-mount electronics tested on a separately controlled thermal platform. This twelve by twelve-inch thermal platform is controlled within a temperature chamber. The coolant valve has a box that is mounted outside the Temperature Chamber. This has become a popular way to test aerospace and automotive components. The thermal stresses applied better simulate real-world conditions. The HBC144 2.0 is available only from TotalTemp Technologies Inc.

Temperature Chambers for flexible thermal tensile testing. Customers use a video extensometer to measure longitudinal strain between two applied lines at various temperatures to determine tensile characteristics of the test medium. Range -160 to 300°C and cooled using liquid Nitrogen.