Typical thermal control for modern product testing uses a PID (Proportional, Integral,& Derivative) control algorithm to provide precise temperature control in changing environments. Other algorithms can be equally successful but the PID algorithm is generally the most widely used. Proper tuning of the temperature control algorithm requires some tradeoffs between fast response and precise control.

Proper adjustment of the setup parameters in the PID temperature control algorithm can make some of these need trade-offs. This document is not so much about adjusting PID parameters, but more about starting with a good strategy.- So first… the control sensor must also be located in the optimum location to control well. If there is a long lag between the time that the heat or cooling is turned on and when the sensor detects it, fast accurate control will not be possible.

You may never be able to achieve the desired temperature control if the temperature sensor is not properly located. For the fastest response, the sensor should be fairly close to the driving heat and cool sources. For temperature readings that most closely represent the temperatures of the device under test, the sensor should be located on or at least closer to the actual device. Modern control algorithms can help with a best-of-both approach.

For many years algorithms have been used to improve accuracy and testing times with two or more sensors. Algorithms based on a careful summation of two or more sensors or PID algorithms will often greatly improve thermal response. By defining a measurement location of concern on the device under test, allowable overshoot of that point, and allowable overshoot of the driving thermal control source, the algorithms are known as cascade control can carefully apply heating and cooling to achieve setpoints quickly and accurately.

Cascade control graph is shown achieving product setpoint quickly without overshoot.

Cascade control is often pretty easy, once all is set up properly. The algorithms will work well allowing the desired temperature to be achieved but in some cases, unexpected things can muck up the process. Things like devices of unusual geometry, unusual heat conduction, or dissipation characteristics, required special test fixturing and other specific challenges. Many of these obstacles can make appropriate sensing points difficult to determine or achieve.

Another alternative to consider is: Given the proper conditions and the understanding that simpler is often better, in some cases it is better to simply control strictly with a sensor at the device. Generally, the conditions that make that work well are 1) Fairly low mass device 2) Minimal heat active dissipation 3) Fairly good heat path between heat source and device. We work mainly with thermal platforms. With platforms, a good heat path would mean good surface contact to the plate, minimal vertical geometry above the plate. The control point in the platform corresponds to the airstream temperature for a chamber. In most cases that don’t change unless the original design of the chamber or thermal platform is altered. Adjustments to the PID algorithm (larger P term) may be necessary however to accommodate the longer thermal path to the sensor.

As a third alternative, sometimes a preferable solution to good control is to simply work around known latency and accuracy issues. If time permits, waiting for a setpoint to be achieved may be preferable to driving systems with intentional overshoot.

When using a thermal platform alone, particularly without an active or passive enclosure (temperature conditioned airflow over the product) there will always be some gradient between the sensor reading in the driving platform and the device on top of the platform. The gradient is mostly due to unbendable laws of physics and also only minimally due to something short of best perfect / best practical thermal designs. In a chamber, the device will usually eventually reach the air temperature unless it is actively producing heat. In any event, most practical gradients are repeatable and predictable. Sometimes it may be best to just specify the temperature accuracy desired, and do a few tests, empirically determine when the setpoint is within the acceptable range at the point(s) of interest and also if any offset is required to compensate for known gradients. Initially more complicated but no further hardware or algorithm adjustments are required.

To bring the three discussed control strategies together for comparison with example photos of setups:

1) Generic Control– at the platform (or air temperature for chambers).

Platform temperature is controlled by a probe embedded in the plate.

The device is directly on the platform surface.

Generic Control Strengths

Simplest, most straightforward general purpose applications

Generic Control Weaknesses

May result in slow or inaccurate results, possibly requiring user compensation by shifting setpoints or settling time rules.

2) Cascade Control- using two sensors to control better

The second Sensor with Cascade Algorithm helps compensate for thermal lag when the point of concern on the device is somewhat isolated from the driving source by a massive fixture or another thermal obstacle.

Cascade Control Strengths

Smarter software helps achieve better & faster temperature control.

Cascade Control Weaknesses

More complicated, more difficult to set up, more things to go wrong.

Extra sensing hardware and software required.

3) Control only at Device

When the device and any fixturing between platform and device are not massive, good control can be achieved by strictly controlling from a point on the device. Any gradients between platform and device are eliminated.

Device Control Strengths

Simple configuration, Only the true temperature of the product is taken.

Device Control Weaknesses

It May require slowing down or detuning of the temperature control algorithm to prevent oscillations.

Extra safety measures might be recommended to prevent open loop heating/cooling if the sensor can be detached from the device.

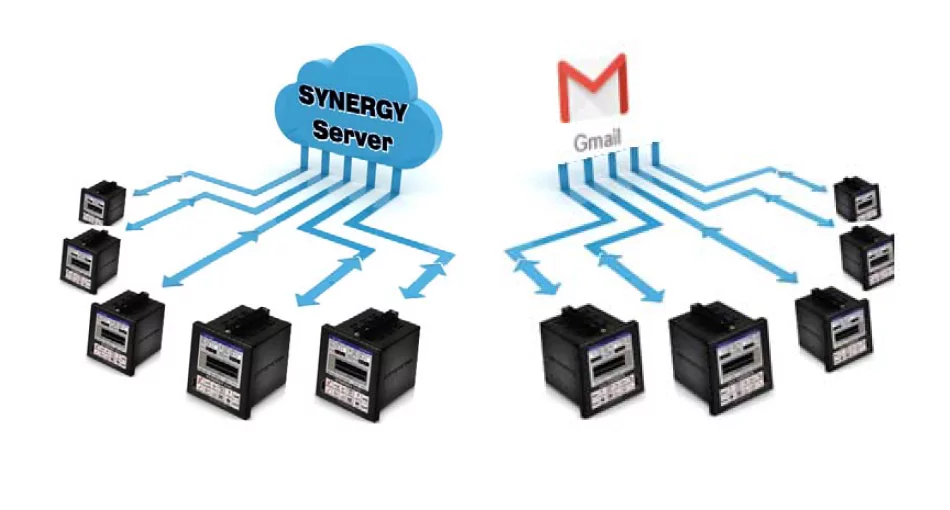

The Tidal Engineering Synergy controller that TotalTemp Technologies uses can make the best of any of these three control strategies. We support any and all of these strategies and are here to help with your temperature control and thermal testing requirements.