That’s just the way it is done…

Yes, we all have heard that or some similar version at least a few times over history.

Yes, we all have heard that or some similar version at least a few times over history.

…And understandably for many things. Clearly, when there is work to be done, there are benefits to following tried and tested methods that are known to produce expected good results.

It may be a cop-out for not taking time to explain or re-think the latest methods or it may be that there truly has been a lot of thought put in and a certain existing methodology really has merit above others.

Temperature testing in a chamber is “Just the way it is done” That may be a good heuristic to follow, or not.

Methodologies change, occasionally rules of thumb do, but the laws of thermodynamics, not so. Some technologies evolve pretty quickly when a new and better way is obvious. CRT monitors, for example, made the exit quickly, GPIB not so. That’s a whole separate story but there are valid arguments why some say ‘Viva GPIB‘.

So, to the point, we don’t foresee standard or custom temperature chambers ever exiting the scene. New methods do evolve. When you look at a large temperature chamber in the lab, you don’t have to think about an old tube monitor. Think instead of a more optimal solution. The Hybrid Benchtop Chamber can be thought of as an extension of the capabilities of either a temperature chamber or a thermal platform. Small chambers are more efficient, take up little space, and have the versatility to perform most thermal testing tasks right on the benchtop.

Thermal platforms (hot & cold plates) as an alternative to chambers can handily improve the speed of many thermal testing tasks, especially for testing devices that are more massive, with higher power dissipation and devices that have at least one flat conductive surface.

Especially when temperatures are not so extreme, some people will use thermal platforms with no cover at all. A variety of Polycarbonate covers (shown below) are available that reduce condensation, corrosion plus keep temperature-shifting air currents away from devices under test. A dry Nitrogen purge added to covers further reduces the effects of water condensation on the device while only minimally affecting the thermal performance. One further step in thermal performance enhancement is to add the conditioning option to the purge system. The purge gas is run through an extra heat exchanger in the platform as indicated here using arrows.

This simple solution gets the air temperature inside a cover close to the platform temperature which is very beneficial for reducing thermal gradients. Unfortunately, there will always be some gradient between the platform temperature and air temperature. The Hybrid Benchtop Chamber optimizes the performance boost with greater airflow and the air temperature is actually controlled to the same or independent temperature from the platform. Temperatures can be adjusted manually or with advanced temperature control algorithms to help get the whole device to the required temperature as quickly as practical or desired.

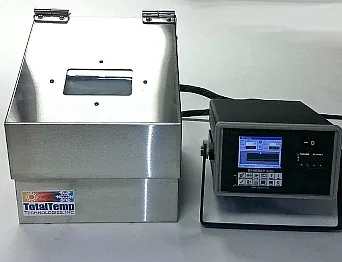

Combining convection and conduction to enhance thermal test performance is a big advantage when it comes to getting thermal testing done in a minimal amount of time. Below right HBC144N and below right is the HBC49N

Often cutting test times in half! At the same time, the Hybrid Benchtop chamber with Synergy Nano controller provides verification that one or several measurement points on the device actually achieved the required temperature profile. PDF reports of results can be automatically printed directly to a network printer or FTP file destination.

The Hybrid Benchtop Chamber is a performance advancement of thermal platforms as well as an advancement in small benchtop chambers, combining the benefits of both. It can even be retrofitted to existing Thermal Platforms.

And remember, If it turns out that the “Traditional way it is done” is the way it should be done, the chamber or platform can be used by itself as a small benchtop chamber or thermal platform.

Talk to us about your RF / Electronics / Power thermal testing requirements. We have qualified people here to answer your thermal testing questions.