Spot Cooling with Vortex Tubes – a Viable Option

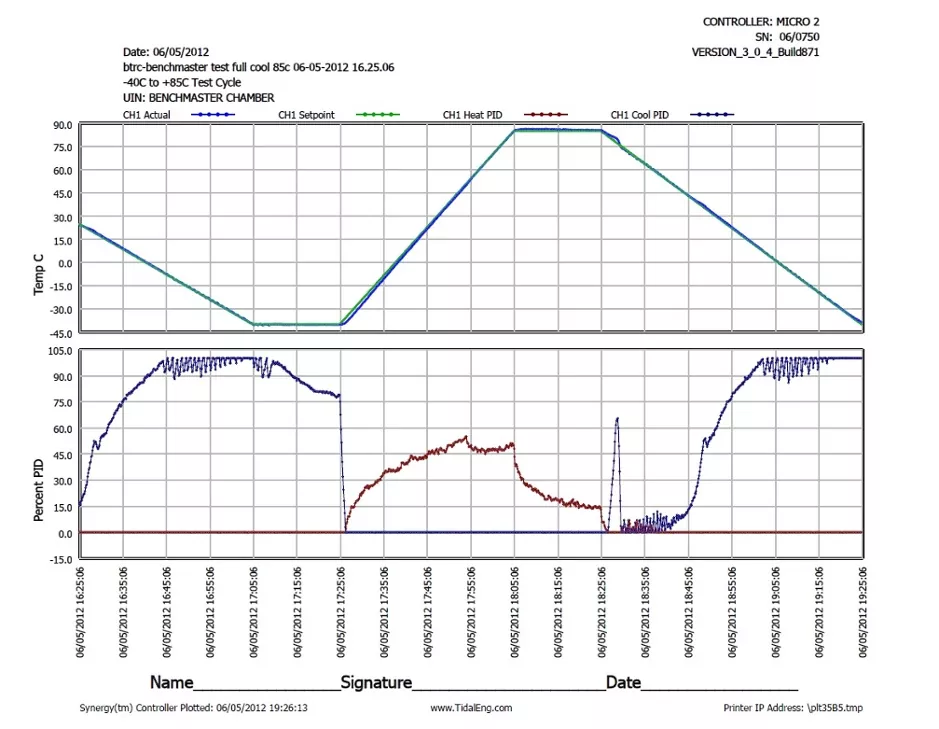

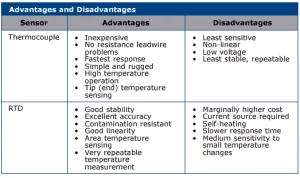

When using temperature chambers or thermal platforms to do thermal testing, the heating of devices tends to be more or less straightforward. Generally, electrical resistance heating, be it conductive or convection (or even radiant) is the best, cheapest, and most easily controllable method.

However when it comes to cooling, there are a few more options, the primary ones being mechanical refrigeration, expendable cryogenic gas such as L-CO2 or L-N2, Peltier (thermoelectric), or – for some, generally smaller applications, vortex tubes are also an option.

Not to be confused with ordinary Venturi tubes, the official name of the device is the Ranque-Hilsch vortex tube. These clever devices are able to provide a surprising amount of refrigeration capacity from compressed air alone. They are best for small lower-cost spot cooling applications since they are a lot simpler and easier to maintain than refrigeration systems. They are somewhat less efficient at cooling than a typical refrigeration system. Efficiency is comparable to Peltier cooling.

The summary description of the operation from Wikipedia: Pressurized gas is injected tangentially into a swirl chamber and accelerated to a high rate of rotation. Due to the conical nozzle at the end of the tube, only the outer shell of the compressed gas is allowed to escape at that end. The remainder of the gas is forced to return in an inner vortex of reduced diameter within the outer vortex…

The main physical phenomenon of the vortex tube is the temperature separation between the cold vortex core and the warm vortex periphery. The vortex tube is essentially a rotors turboexpander. It consists of a rotor’s radial inflow turbine (cold end, in the center) and a rotors centrifugal compressor (hot end on the periphery). The work output of the turbine is converted into heat by the compressor at the hot end. This explanation of the heating/chilling effect stems from the law of energy conservation.

For the practical application, a small vortex tube with 100 psi room temperature air and an available flow rate of 5-10 SCFM can produce a temperature drop of 50 degrees C and removal of 2800 BTU/Hr., or around 800 Watts.

A couple of realistic concepts and limitations to using vortex tubes:

1. Air source must be clean and of good capacity per above, this will enable long life with little or no maintenance

2. Use of proper muffler is suggested to minimize exhaust noise

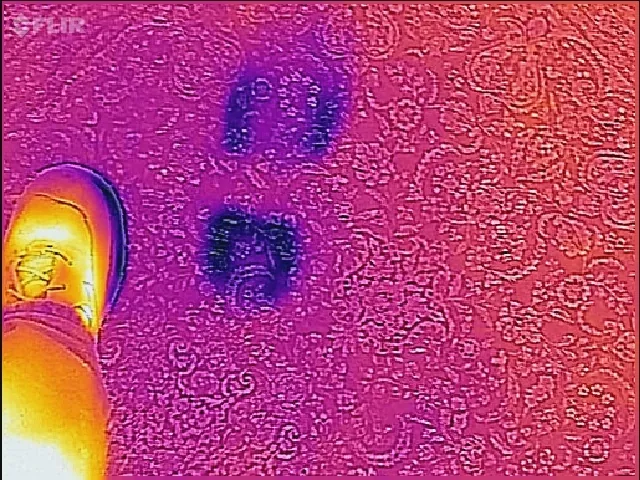

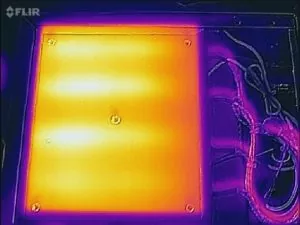

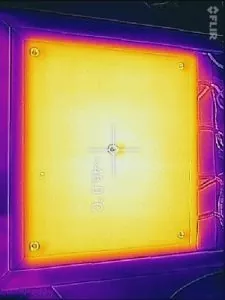

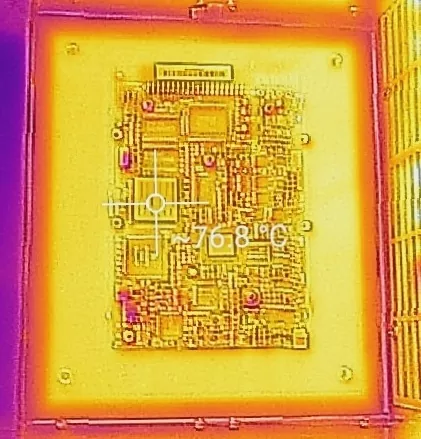

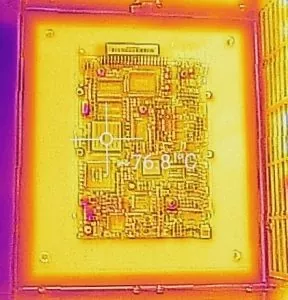

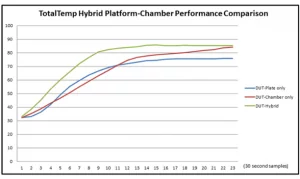

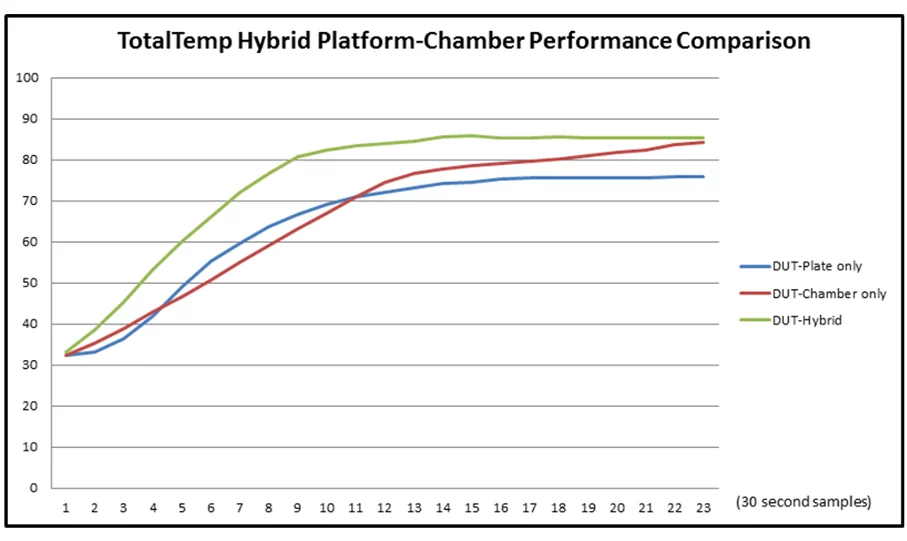

3. Small active loads on cold plates or chambers will work well with vortex tubes

4. Systems can be optimized for more capacity or more temperature differential.

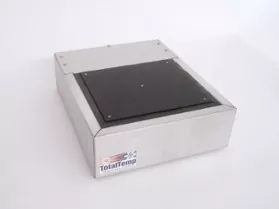

5. Properly integrated into a hot-cold plate or small chamber, a vortex tube chiller may be the best choice for small low capacity cooling needs.

TotalTemp Technology is happy to talk with you about your thermal testing requirements.

Feel Free to reach out with your questions.

Vs.

Vs.